Ultimate Guide to Sealed Power Connecting Rod Bearings 1986 Mercruiser 7.4 .020

In the world of marine engines, the reliability and efficiency of your vessel can often depend on small yet critical components. One such element is the connecting rod bearing. The focus of this guide is on the Sealed Power Connecting Rod Bearings 1986 Mercruiser 7.4 .020, which have been engineered to meet the demanding conditions of marine applications.

With a special emphasis on the .020 clearance specification, this article will explain why proper bearing clearance is vital, delve into the features that set Sealed Power bearings apart, and provide practical instructions for installation and ongoing maintenance.

Background and Context

Understanding Connecting Rod Bearings

Connecting rod bearings are essential for reducing friction between the connecting rod and the crankshaft, ensuring smooth operation under varying loads. In marine engines, where the operating conditions can be both rigorous and variable, these bearings maintain a crucial oil film that prevents metal-to-metal contact. This protective film is especially important in preventing premature wear and ensuring the longevity of the engine.

Overview of the 1986 Mercruiser 7.4 Engine

The 1986 Mercruiser 7.4 engine is a revered model in the marine industry, known for its robust performance and reliability. Its design caters to both recreational and commercial marine applications, making it a popular choice among boat owners. The engine’s bottom-end, where connecting rod bearings operate, is critical to overall engine performance and durability.

Introduction to Sealed Power

Sealed Power is a brand that stands out due to its commitment to high quality and precision engineering. Their connecting rod bearings are specifically designed to handle the high stresses and demanding conditions found in marine engines. By ensuring the correct clearance—such as the .020 specification—the bearings help maintain optimal lubrication, reduce friction, and enhance overall engine performance.

Technical Deep Dive: The .020 Specification

What Is the .020 Clearance?

The .020 specification refers to the recommended oil clearance between the bearing surface and the connecting rod journal. This clearance is not arbitrary; it plays a pivotal role in maintaining the correct oil film that acts as a cushion during engine operation. When the clearance is set to .020 inches, it allows for proper oil flow, which in turn ensures effective heat dissipation and minimizes wear.

Why Precise Clearance Matters

Proper clearance is critical for several reasons:

- Lubrication Efficiency: The .020 gap allows oil to continuously circulate, ensuring that every part of the bearing is adequately lubricated.

- Heat Dissipation: By maintaining the correct clearance, the oil is better able to carry heat away from the friction surfaces, reducing the risk of overheating.

- Wear Prevention: Adequate clearance minimizes direct metal-to-metal contact, significantly extending the life of the engine components.

To illustrate the importance of proper clearance, consider the table below:

| Parameter | Optimal Value | Functionality Impact |

|---|---|---|

| Oil Clearance | 0.020 inches | Ensures proper lubrication & cooling |

| Temperature Regulation | Maintained | Prevents overheating |

| Friction Reduction | Maximized | Minimizes wear and prolongs engine life |

This table clearly demonstrates how critical the .020 clearance is for the efficient performance of your engine.

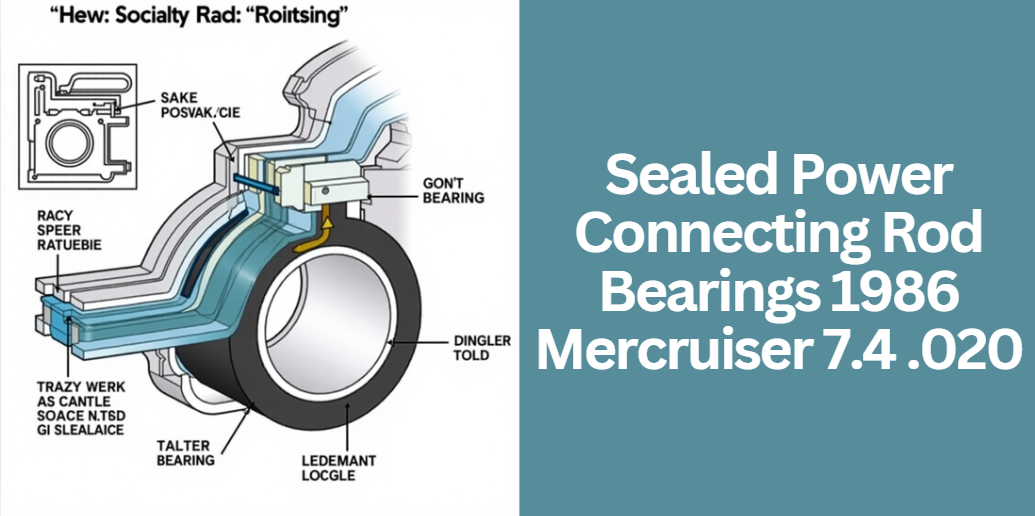

Visual Aids and Diagrams

Imagine a detailed schematic that shows the precise gap between the connecting rod bearing and the journal. Visual aids like diagrams not only help in understanding the concept but also serve as an excellent reference during the installation process. Such diagrams can highlight the exact measurement points and illustrate how even minor deviations can lead to performance issues.

Sealed Power Bearings: Features and Benefits

Quality and Durability

Sealed Power Connecting Rod Bearings 1986 Mercruiser 7.4 .020 are manufactured using advanced materials and innovative techniques. The use of high-grade alloys and precision machining ensures that these bearings can withstand the high stresses typical in marine engines. Their superior construction translates into longer service intervals and enhanced overall engine performance.

Performance Benefits

By choosing Sealed Power bearings, marine engine owners benefit from improved engine efficiency and reduced friction. The correct oil clearance of .020 inches is maintained consistently, which not only reduces wear but also promotes smooth engine operation even under extreme conditions. Users have reported better fuel economy and a noticeable reduction in engine noise when the bearings are installed correctly.

Comparative Analysis

A side-by-side comparison of Sealed Power bearings with other popular brands shows a clear advantage in terms of durability and performance. The table below offers a feature-by-feature comparison:

| Feature | Sealed Power | Competitor A | Competitor B |

|---|---|---|---|

| Bearing Material Quality | High-grade alloys | Standard alloys | Mid-range alloys |

| Consistent .020 Clearance | Precisely maintained | Variable performance | Occasional deviations |

| Engine Longevity | Extended service life | Standard longevity | Lower durability |

| Manufacturer Reputation | Industry-leading | Well-known | Niche market |

This comparative analysis clearly positions Sealed Power as the superior choice for marine engine enthusiasts.

Installation Process and Best Practices

Pre-Installation Checklist

Before beginning the installation of Sealed Power Connecting Rod Bearings 1986 Mercruiser 7.4 .020, it is essential to gather all the necessary tools and materials. Ensure you have the following items ready:

- Precision micrometers

- Plastigage for measuring clearances

- Clean rags and appropriate lubricants

- Service manual and technical documentation

Step-by-Step Installation Guide

Installing these bearings requires a methodical approach:

- Preparation: Begin by thoroughly cleaning the connecting rod and journal surfaces. Any residual debris can compromise the bearing installation.

- Measurement: Use a Plastigage tool to measure the existing clearance. This step is critical to confirm that the gap matches the recommended .020 inches.

- Installation: Carefully position the new bearing into place, ensuring it seats perfectly without misalignment. Follow up by reinstalling the connecting rod.

- Verification: After installation, re-check the clearance to ensure that it remains within the optimal range. Proper installation is confirmed when the bearing maintains the .020 clearance under all operating conditions.

Common Pitfalls and Troubleshooting

During installation, technicians may encounter common issues such as misalignment or inconsistent oil clearance. It is important to refer to the service manual and Sealed Power guidelines to troubleshoot these issues effectively. Ensuring that every step is meticulously followed helps avoid potential engine damage.

Maintenance and Inspection Guidelines

Regular maintenance is crucial to keep the Sealed Power Connecting Rod Bearings 1986 Mercruiser 7.4 .020 performing at their best. A proactive maintenance schedule can help in detecting early signs of wear and prevent major engine failures.

Routine Maintenance Schedule

To maintain optimal performance, set up a regular maintenance plan that includes:

- Periodic oil changes

- Regular inspection of bearing clearances

- Detailed checks of the entire bottom-end assembly during scheduled service intervals

Inspection Techniques

Technicians should use precision measurement tools to inspect the bearing clearance. Look for any signs of excessive wear or damage. If any discrepancies are found, it is advisable to address them immediately to prevent further issues.

Troubleshooting Performance Issues

If you notice a drop in engine performance, unusual noises, or increased oil temperatures, it may be indicative of improper clearance or worn-out bearings. Follow these steps:

- Re-measure the clearance using a Plastigage tool.

- Verify that the oil is circulating properly.

- If necessary, replace the bearings following the detailed installation guide provided above.

Real-World Case Studies and User Experiences

Success Stories

Many marine engine enthusiasts have experienced significant improvements in engine performance after switching to Sealed Power Connecting Rod Bearings 1986 Mercruiser 7.4 .020. For example, one seasoned technician shared how his engine’s noise levels dropped considerably, and overall efficiency improved after ensuring the .020 clearance was properly maintained.

Expert Insights

Experts in marine engine maintenance agree that the use of high-quality bearings such as those from Sealed Power is a cornerstone of effective engine performance. Their insights underline that precision in installation and adherence to recommended clearances are key to unlocking the full potential of your marine engine.

Comparative Analysis: Sealed Power vs. Competitors

Below is a detailed table comparing the features of Sealed Power Connecting Rod Bearings 1986 Mercruiser 7.4 .020 with other brands:

| Aspect | Sealed Power | Competitor A | Competitor B |

|---|---|---|---|

| Material Quality | High-grade alloys | Standard alloys | Mid-range alloys |

| Precision Clearance | Consistently maintained at .020 | Inconsistent performance | Occasional deviations |

| Durability and Longevity | Extended service life | Standard longevity | Lower durability |

| Manufacturer Reputation | Industry-leading | Well-known | Niche market |

This table illustrates the clear advantages of choosing Sealed Power for ensuring optimal engine performance and reliability.

Frequently Asked Questions

How do marine environmental factors like saltwater exposure and high humidity affect these bearings?

Marine environments introduce challenges such as corrosion and salt buildup, which can affect bearing surfaces and lubricants. To counteract these issues, regular cleaning, the use of corrosion-resistant coatings, and scheduled maintenance are recommended to ensure that the bearings remain in optimal condition despite the harsh conditions.

What factors, aside from the recommended clearance, can impact the longevity of these bearings?

While proper clearance is crucial, the overall lifespan of Sealed Power Connecting Rod Bearings 1986 Mercruiser 7.4 .020 can also be influenced by factors such as the quality of lubricating oil, the operating environment, and the presence of any abnormal engine vibrations. Consistently using high-quality oil and ensuring the engine operates within specified temperature ranges can further enhance bearing life.

Are these bearings compatible with other marine engine models or only the 1986 Mercruiser 7.4?

Although these bearings are specifically designed for the 1986 Mercruiser 7.4 engine, some technical similarities may allow them to be used in other models with similar engine configurations. However, it is crucial to consult the engine manufacturer’s specifications and service manuals before considering cross-compatibility to ensure proper fit and performance.

How do temperature fluctuations impact the performance of these bearings?

Temperature variations can affect both the metal components and the oil viscosity in the engine. In extreme conditions, high temperatures may lead to thermal expansion, potentially altering the bearing clearance, while colder temperatures can thicken the oil, impacting its lubricating properties. Maintaining a stable operating temperature is key to preserving optimal bearing performance.

What is the expected operational lifespan of these bearings under normal marine conditions?

Under regular maintenance and proper installation, Sealed Power Connecting Rod Bearings 1986 Mercruiser 7.4 .020 are engineered to provide long-term durability. Their lifespan will depend on factors such as engine load, duty cycles, and environmental conditions, but they are generally designed to last through multiple service intervals before any significant wear is observed.

Conclusion

In summary, understanding and maintaining the precise clearance of Sealed Power Connecting Rod Bearings 1986 Mercruiser 7.4 .020 is essential for achieving optimal performance and longevity in your marine engine.

This comprehensive guide has explored the critical technical aspects, installation processes, and maintenance tips that ensure your engine runs smoothly under even the most demanding conditions. By following the expert advice and detailed procedures outlined in this article, you can maximize the efficiency and durability of your 1986 Mercruiser 7.4 engine.

This guide stands as a definitive resource, offering not only the technical details required for precise maintenance but also the practical insights that come from real-world experiences and expert recommendations. Enjoy improved engine performance and peace of mind with the right tools and knowledge at your fingertips.

More Posts

Jennifer Harman by Jackie Allison Book – A Complete Guide to the Poker Legend’s Biography

Comprehensive Guide to the Augusta Precious Metals Lawsuit

Ultimate Guide to Black Madeira Fig Tree For Sale San Luis Obispo

Market Trend FTAsiaFinance: A Comprehensive Guide to Asia’s Financial Evolution

EcVh0 dForce Master How-To: The Ultimate Guide for Daz 3D Users